Additive for Direct Energy Deposition (DED) is available within ESPRIT®, the full-spectrum CAM system, offering programming, optimization, and simulation for both additive and subtractive processes in one integrated solution.

-

Side-by-side additive and subtractive programming

-

Natural workflow for hybrid or dedicated additive machines

-

Stock-aware cycles for both additive and subtractive

-

Full simulation of both additive and subtractive processes

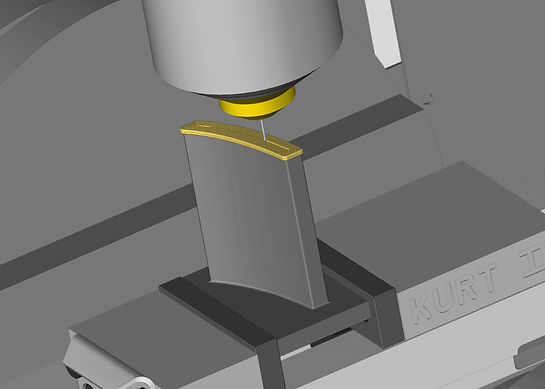

DED 3+2

This 3-axis DED cycle is used for builds where the workpiece may be oriented in 5-axis, then built layer-by-layer using a 3-axis process. Stock allowance may be added around the build for subsequent finishing operations using traditional subtractive processes. The user may choose between contouring and contouring with filling strategies including offset, raster, and zig-zag to produce the desired result.

-

3-axis DED with 4th or 5th axis positioning

-

Filling strategies for solid workpieces

-

Added stock for subtractive finish machining

DED 4-Axis

.png)

Rotary DED has the same capabilities as 3+2 with the addition of allowing deposition while simultaneously rotating the workpiece around an axis. The trajectories for the build are made of circular offsets using a specializer slice to build the feature, layer-by-layer.

-

Includes 3+2 capabilities plus

-

Simultaneous 4th axis rotations

-

Circular trajectories using a specialized slicer to build the feature, layer-by-layer

DED 5-Axis

5-axis DED is used when the part must be tilted dynamically while material is being added. The cycle will automatically calculate simultaneous 5-axis motions to properly tilt the head whenever it is needed for proper material deposition, enabling a simultaneous 5-axis building process that can include timing for any required cooling.

-

Automatic 5-axis motions for optimal material deposition

-

Optional timing for cooling

Machine-Aware Direct Energy Deposition

ESPRIT provides a natural workflow for programming direct energy deposition machines. The machines may be dedicated additive machines or hybrid additive machines that also perform traditional subtractive machining.

Using ESPRIT’s concept of machine awareness, a digital twin of the machine is used for programming, optimizing, and simulating additive and subtractive manufacturing processes. From large gantry machines to small part Swiss-style lathes, ESPRIT supports every conceivable configuration of CNC machine, covering a full spectrum of market needs from medical to aerospace and beyond.

Within ESPRIT, an additive cycle is created and treated like all other machining cycles which may be combined in any order at any time. The automatic link generator provides efficient and safe positioning between additive, cutting and non-cutting operations, tool changes, and part handling, which are optimized for the machine and part setup.

Both the links positioning moves as well as the additive and subtractive cycles take into consideration the remaining stock, including stock added by the additive processes, so all moves are collision-free and optimized for cycle time. Meanwhile, the simulation shows exactly what will happen at the machine, previewing the entire machining process.

-

For any class of CNC machine — from gantry to Swiss-style

-

Side-by-side additive and subtractive programming

-

Natural workflow for hybrid or dedicated additive machines

-

Stock-aware cycles for both additive and subtractive

-

Full simulation of both additive and subtractive processes

Additive for DED Features

-

Specialized trajectories (toolpaths) for additive processes

-

Full-spectrum toolpaths for subtractive processes

-

Multitasking, multifunction, synchronized 3+2- and 5-axis programming

-

Simulation, verification of additive and subtractive processes

-

Universal post-processing for any CNC machine tool

-

Built in to the native ESPRIT workflow